CPM 154

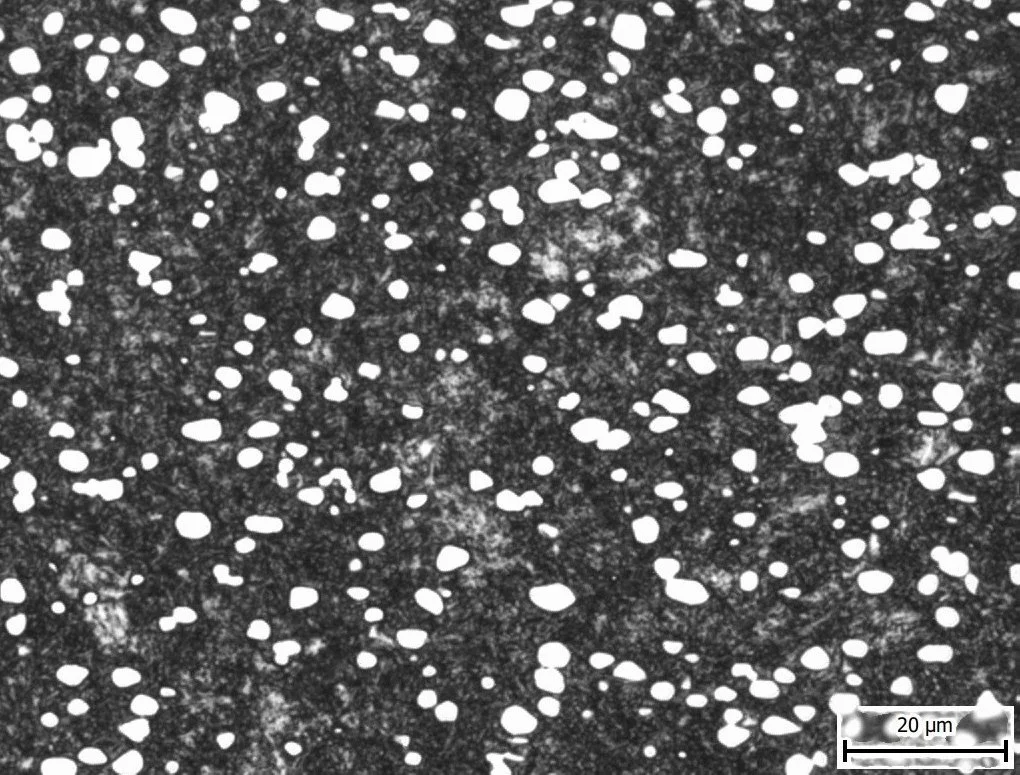

CPM 154 has a large volume (16%) of chromium carbides. The carbides are much smaller than the chromium carbides seen in conventionally made steels like 440c, SKD11, and VG-10. Since chromium carbides are softer than conventional abrasives CPM 154 can easily be sharpened on ceramic or natural stones.

CPM 154 is a powder metallurgy steel with similar characteristics to CPM D2. Compared to CPM D2, CPM 154 sacrifices some toughness and potential hardness for an increase in corrosion resistance. CPM 154 is a great choice for those who want more wear resistance and corrosion resistance over AEB-L. I harden CPM 154 to between 62 and 64 RC depending on the desired characteristics

Credit to Dr Larrin Tomas of www.knifesteelnerds.com