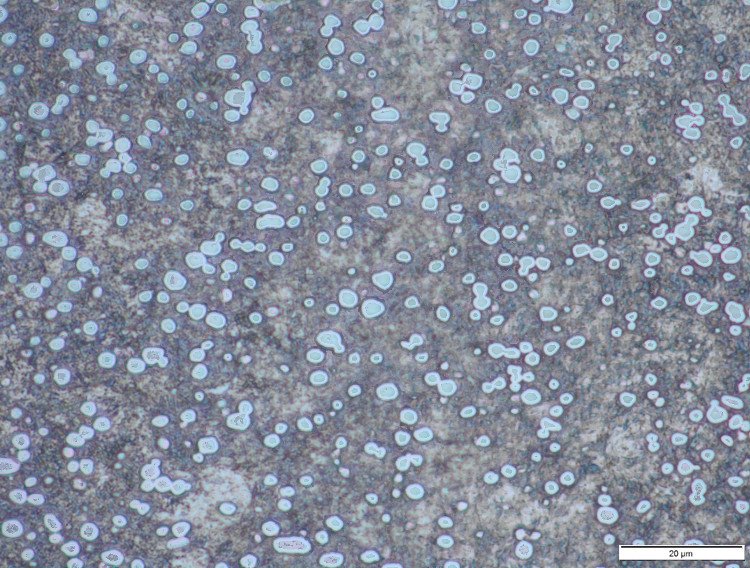

CPM D2

CPM D2 has a moderate volume (15%) of chromium carbides. The carbides are much smaller than the chromium carbides seen in conventionally made steels like 440c, SKD11, and VG-10. Since chromium carbides are softer than conventional abrasives CPM D2 can easily be sharpened on ceramic or natural stones.

CPM D2 is a powder metallurgy version of a a steel originally developed for industrial dies. The powder metallurgy process drastically decreases the carbide size, which increases the toughness and potential hardness of the steel. I heat-treat this steel to between 62 and 66 RC depending on the desired characteristics. This is the most wear resistant steel I offer that does not require diamond abrasives

Credit to Larrin Thomas of www.knifesteelnerds.com