S90V

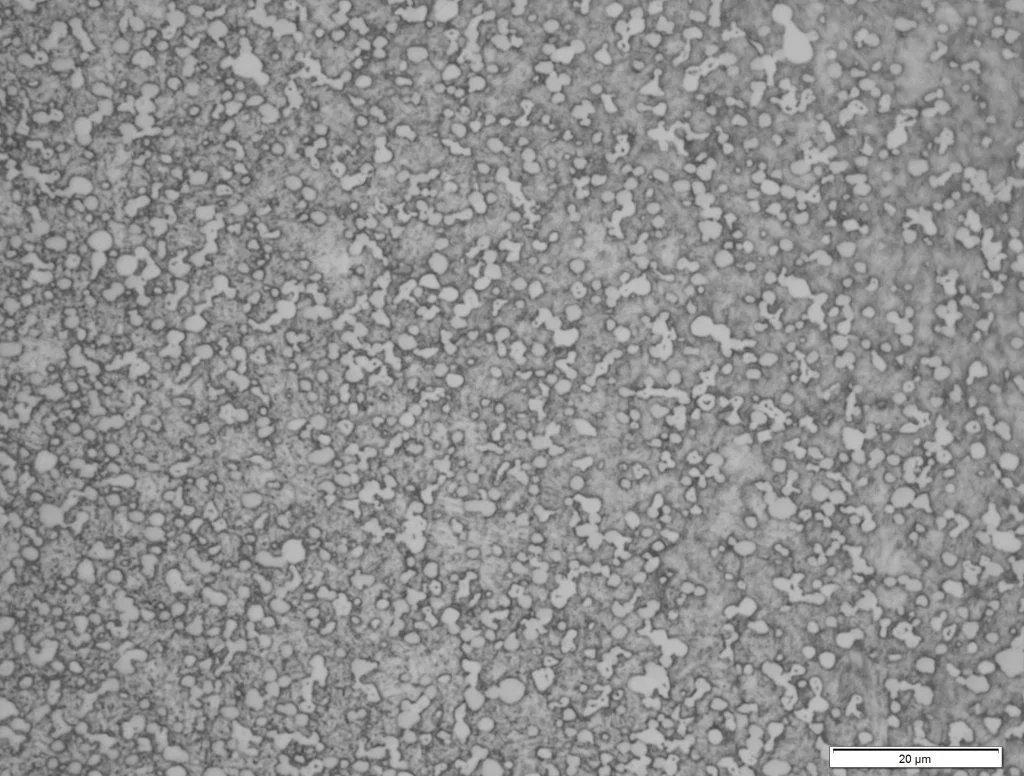

S90V has a very large (21%) volume of fairly small carbides. This is split between 13% vanadium enriched chromium carbide and 9% of the harder MC-type vanadium carbide. Due to its high volume of MC-type carbides, S90V should be sharpened on diamond or CBN abrasives for the best results. If you are interested in more information on this steel I have covered it on my Instagram as part of my ongoing Steel Saturday series!

CPM S90V is a powder metallurgy stainless steel with high vanadium content. It is the most wear-resistant stainless steel I currently work with. CPM S90V offers a significant improvement in wear resistance over CPM MagnaCut at the cost of a reduction in toughness and corrosion resistance. The wear resistance is most similar to CPM 10V however its toughness is much lower. S90V is a good pick for slicing knives and for those with a lighter touch and end grain cutting boards. While it is tougher then common low alloy steels like Aogami Super due to its high carbide volume it susceptible to microchipping when used on hard surfaces, leading to a reduction in edge retention. I harden S90V to 62-65Rc depending on the desired characteristic

Credit to Dr Larrin Thomas of www.knifesteelnerds.com