Z-Max

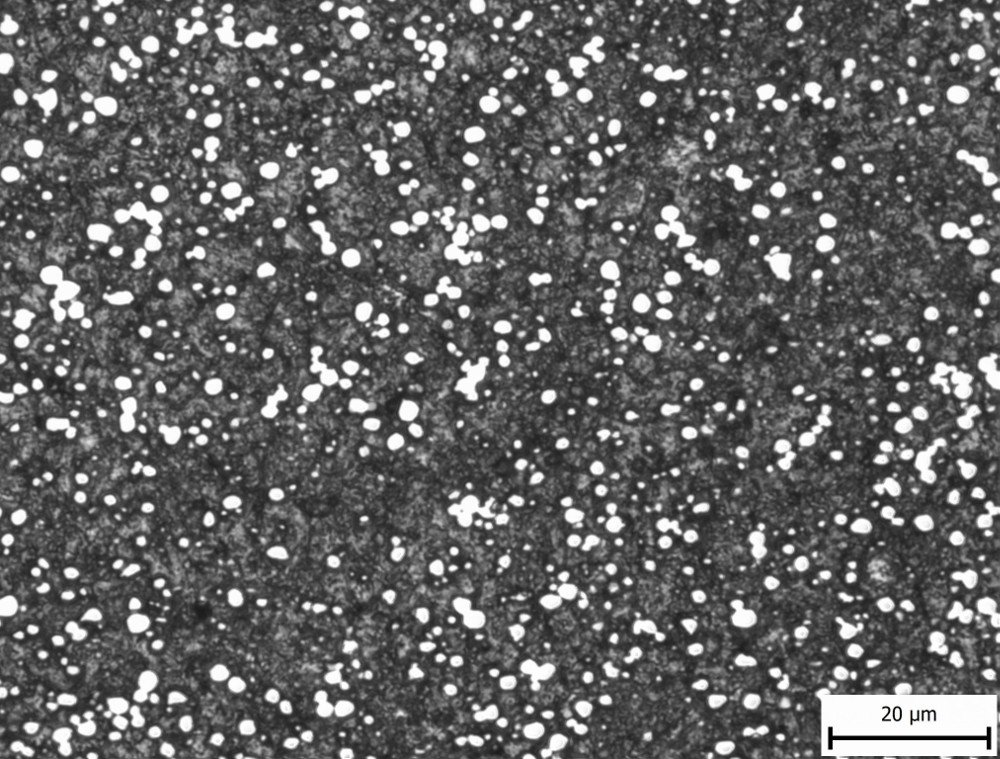

Z-Max has a large volume (21%) of fine carbides split roughly evenly between MC-type vanadium carbides and softer (similar hardness to chromium carbides) high-speed steel carbides. Since the carbides are harder than conventional abrasives this steel is very difficult to sharpen on non-diamond stones. If you are interested in more information on this steel I have covered it on Instagram as part of my ongoing Steel Saturday series! I also have a free article on my Patreon covering the steel.

Z-Max is a powder metallurgy steel that was developed as a replacement for carbide tooling in certain applications. It is currently the most wear resistant steel that I offer. Z-Max has poor toughness similar to 26c3 in the 66 Rc range and somewhat better than Aogami Super at 64 Rc. Due to its high carbide volume, Z-Max is especially susceptible to microchipping if used for cutting on hard surfaces. Z-Max is well suited for slicing knives although for those with good technique and soft cutting boards (end grain or similar) Z-Max can make a great choice for a chef’s knife. I harden Z-Max to 70Rc.

Credit to Dr. Larrin Thomas of www.knifesteelnerds.com